Explore the benefits of AI in supply chain, prioritize high-impact use cases and mitigate risks to implementation.

- Gartner client? Log in for personalized search results.

How AI Is Transforming Supply Chain Management

Likely win or calculated risk: Which one is your supply chain AI investment?

By 2028, expect two transformative shifts to supply chain operations:

25% of KPI reporting will be powered by GenAI models.

Smart robots will outnumber frontline workers in manufacturing, retail and logistics.

Download our AI use case guide to:

Learn the top supply chain AI use cases by business value and feasibility, ranked by Gartner’s tech analysts

Align use cases to your business requirements

See analysis of which supply chain AI investment ranks highest for efficiency and revenue growth

AI is rapidly revolutionizing supply chain management

Capable of transforming strategy and operations, supply chain AI solves the employee productivity conundrum, in which endless productivity tools make only trivial improvements in actual metrics.

Shape AI Strategy

Launch GenAI Pilots

Design the AI Portfolio

Don’t build an AI technical plan until you’ve defined how AI enables strategy

Come next year, 95% of data-driven decisions are expected to be at least partially automated. And yet, only 10% of CEOs say that their business uses artificial intelligence strategically. Even fewer technology leaders (9%) say their business has a clearly defined AI vision statement.

In a recent survey, we discovered that those companies mature in artificial intelligence were more likely to define performance metrics early at the ideation phase of every AI use case.

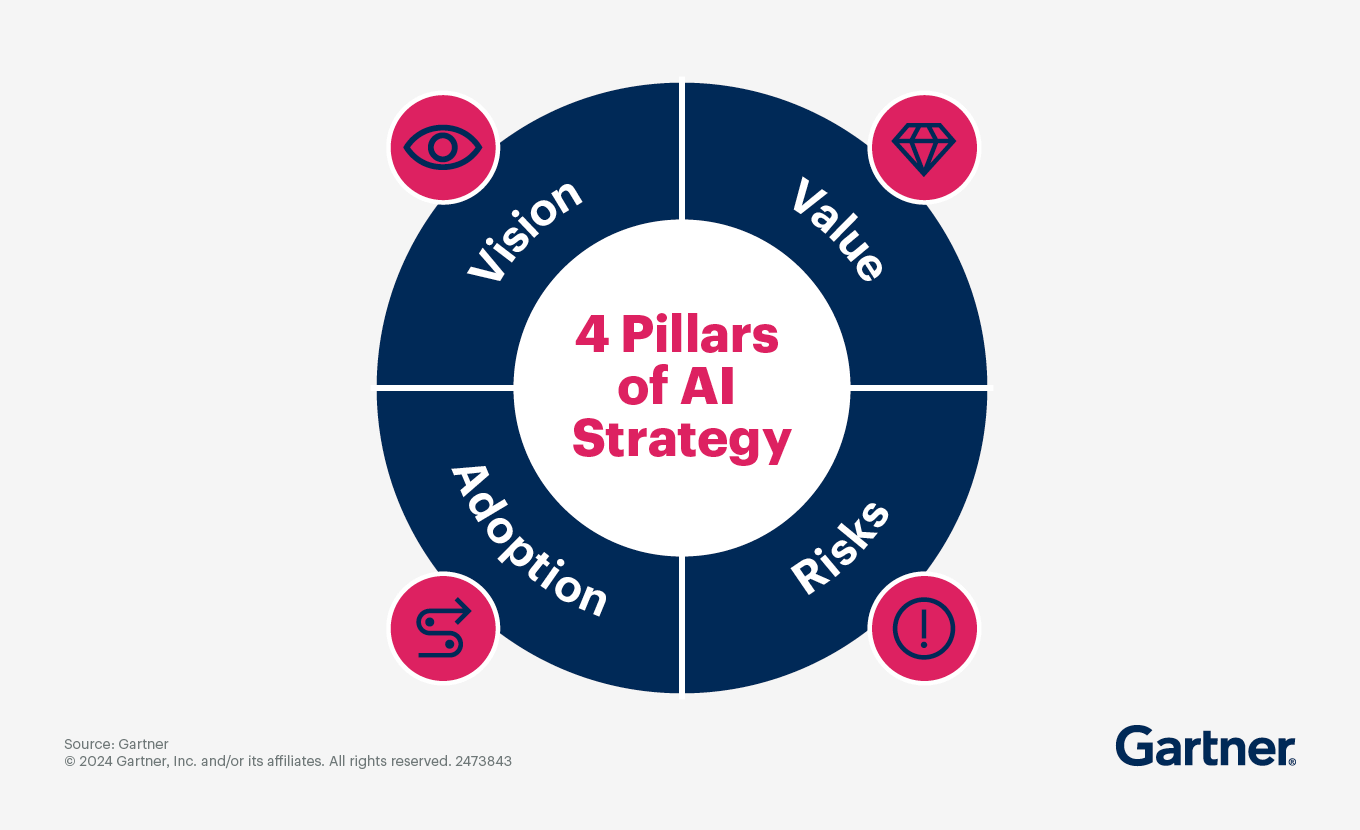

Craft a comprehensive AI in supply chain strategy that not only mitigates risk but also leverages artificial intelligence disruptively to gain a competitive edge. A supply chain AI strategy that is both defensive and competitive addresses the 4 key pillars of AI strategy: vision, value, risks and adoption.

4 pillars of AI strategy

AI vision: Establish your vision for supply chain AI. State clearly how supply chain AI advances supply chain strategy. This is key to encouraging and enabling organizationwide fluency and adoption of AI, and is helpful for funding the right AI in supply chain use cases — ones that will deliver clear return on investment and lead to further innovation. Goals that supply chain AI enables include:

Reduced supply chain costs and higher productivity via process automation

Improved customer satisfaction from increased proximity to the customer

Improved forecast accuracy from predictive analytics

AI value: Identify the organizational barriers that could hinder supply chain AI from succeeding, and leverage change management approaches to remove those hurdles — e.g., size the supply chain AI portfolio and/or pilot supply chain AI projects; establish accountability for AI strategy development and execution; collaborate with IT and data and analytics leaders.

AI risks: Identify the regulatory, reputational, competency, technology and other supply chain risks you may need to mitigate. Mitigation strategies include:

Establishing AI governance

Strengthening cybersecurity

Developing data literacy among the supply chain workforce

AI adoption: Prioritize your supply chain AI initiatives based on their value and their feasibility, as agreed to by both supply chain leaders and other stakeholders in the business. It’s typical for businesses to pursue initiatives where value is high (and risk also tends to be high, i.e., feasibility is low) but avoid projects where feasibility is so low that it makes the project impossible. A use case with a seemingly outstanding value contribution and strong feasibility is either a breakthrough or the market is missing a great opportunity.

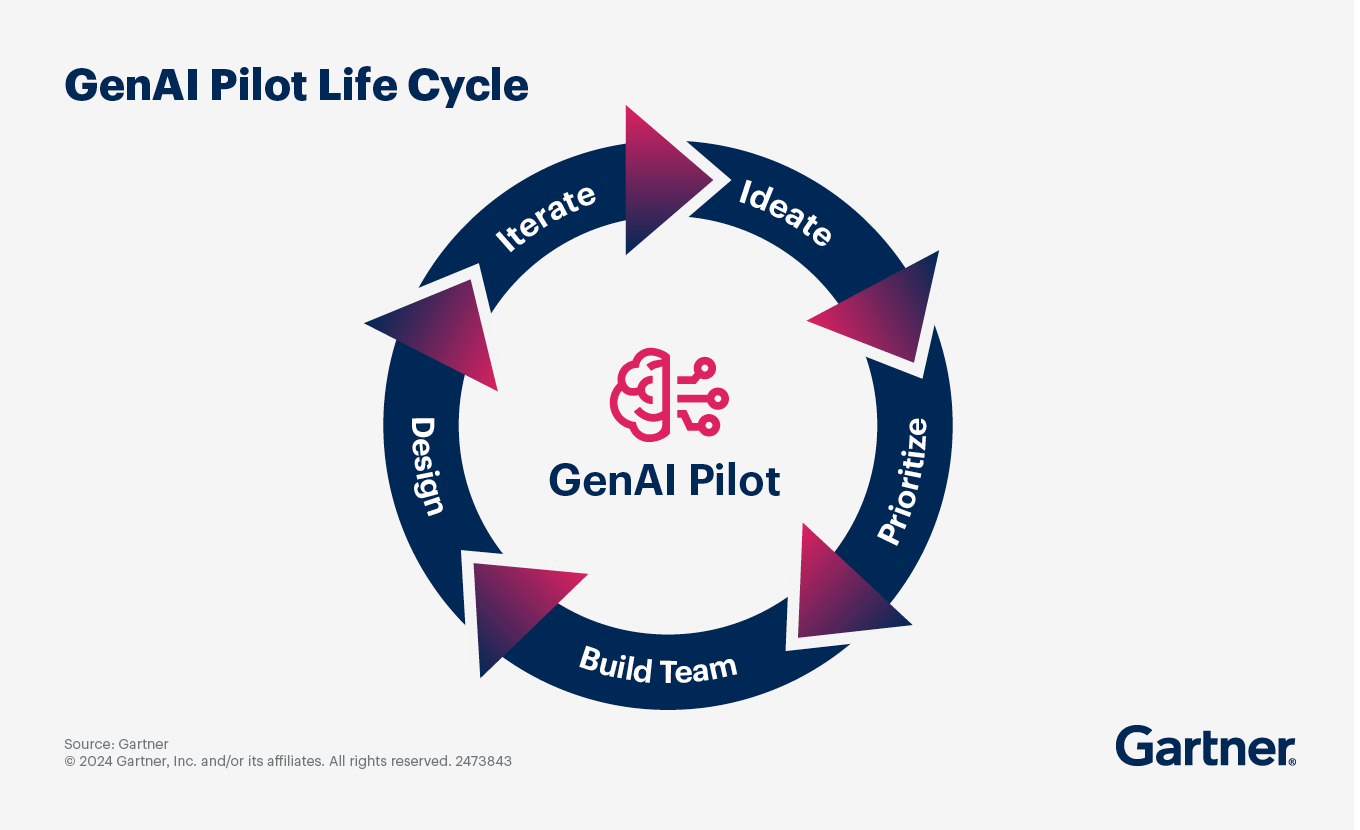

Map short-term GenAI use cases to key supply chain objectives

Core to a successful supply chain AI strategy is a solid understanding of which processes would benefit from implementing AI. But gathering potential use cases for supply chain digital transformation can be overwhelming, evaluating them can be time-intensive, and prioritizing them can be complex. You must consider the practicability, impact and cost of each proposal while also accounting for potential risks and benefits.

Few chief supply chain officers (CSCOs) have a reliable framework to source, organize and assess different proposals from their teams for generative AI. But limited understanding of the precise applicability of GenAI isn’t stopping them from trying to capture first movers’ advantage; almost 70% of business leaders believe the benefits of generative AI adoption outweigh the risks.

To structure GenAI pilots for supply chain optimization, Gartner recommends that CSCOs map short-term GenAI use cases to four overarching supply chain objectives. The long-term impact of generative AI on supply chain planning will undoubtedly evolve, but mapping function-agnostic tasks to supply chain objectives allows CSCOs to quickly pilot generative AI and net potential short-term benefits for their organization.

Supply chain objectives

Defining and implementing a supply chain strategy: This includes designing the strategy and managing its financials and sustainability.

Managing technology: This includes managing data, designing a digital roadmap and leveraging technology investments.

Building an effective organization: This includes executing a talent strategy and establishing the right culture.

Managing supply chain performance: This includes defining and managing processes, developing analytics and governing performance.

Short-term GenAI in supply chain use cases:

Augmenting or creating written content: Draft text outputs based on desired length, style and tone.

Information discovery: Provide answers to questions based on prompts.

Summarization: Summarize conversations, articles, emails and webpages.

Classifying content for specific use cases: Sort content into sentiments or topics that aren’t specifically programmed.

Improving chatbot performance: Improve the bot’s conversational methods and ability to converse naturally and broadly.

Software coding: Generate code, translation, explanation and verification.

In addition to knowing its benefits and use cases, learn the risks and barriers to generative AI adoption. AI models are only as good as the data they are trained on, so incomplete or inaccurate data could lead to incomplete or inaccurate insights. And since the data must also be voluminous, you risk exposing IP and growing your carbon footprint. Learning and experience loss are risks, too. For example, if you rely exclusively on generative AI in supply chain to create supplier risk assessments, that skill among human workers will fade over time.

Investing in supply chain AI: Why, what and how

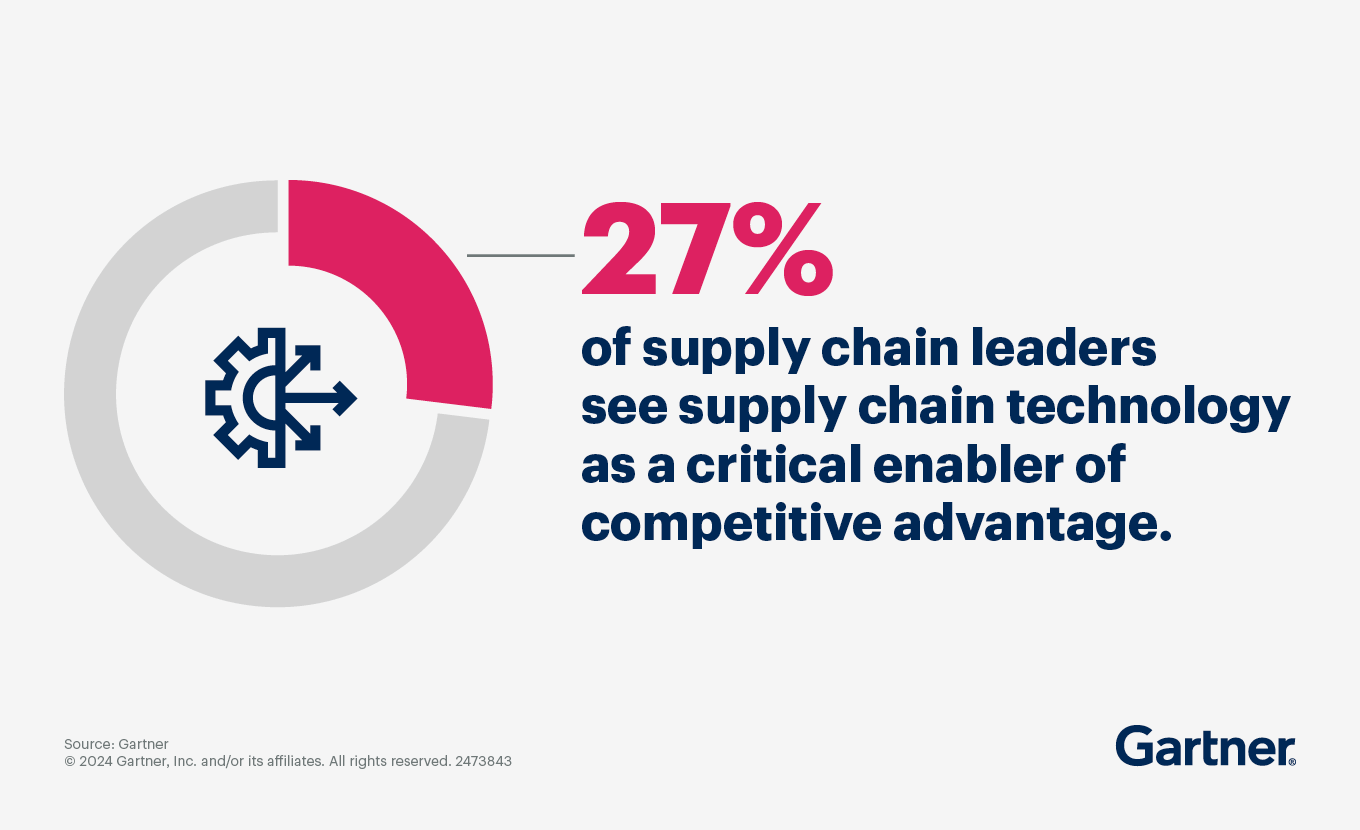

Supply chain leaders see supply chain technology as a critical enabler of competitive advantage. According to a recent survey, 27% say that “gaining competitive advantage” or “addressing competitive disadvantage” is one of their top three goals for investing in emerging technology, and 9% say this is their No. 1 goal.

Behind these future supply chain trends, we identified four major areas of AI technology investment:

Labor: Addressing rising labor costs and labor shortages by supplementing, enhancing or replacing humans with automation. Another capability has to do with motivating the workforce. By 2028, Gartner predicts that 40% of large warehouse operations will have deployed employee engagement tools.

Intelligence: Leveraging technology to make better, faster and more enlightened decisions. As supply chains have become increasingly complex and volatile, decision-making speed and quality persist as a top internal challenge supply chain organizations face. This is motivating companies to invest in a variety of disruptive technologies such as advanced analytics, machine learning (ML) and — most recently — generative AI.

Edge: Blending the value of applications in the cloud with the responsiveness and performance of technologies sitting at the edge. In fact, by 2027, 80% of manufacturing operations management solutions are expected to be cloud-native and edge-driven.

Security: Addressing cyber risks prevalent in supply chain organizations today. Our research shows that by 2026, 15% of supply chain software will actualize software bills of materials (SBOMs) to thwart cyberattacks.

Supply chain AI has the potential to redesign job roles, upend customer demands and transform workplace productivity. But not all supply chain AI use cases are equal. To maintain supply chain cost-efficiency, it’s important to distinguish AI initiatives by those within boundaries, pushing boundaries and breaking boundaries, as explained below.

Everyday AI: This type of AI is typically focused on productivity. While it helps increase efficiency in ordinary tasks, it’s unlikely to create true market differentiation for supply chain organizations.

Boundary-pushing AI: This type of AI aims for a net improvement in larger-scale supply chain operations. It goes beyond everyday, low-risk, productivity-focused use cases, but is not yet significant enough to augment supply chain management in broad terms.

Game-changing AI: This type of AI aims for a net improvement in market leadership. Creative, innovative solutions can augment core operations, lead to new sources of revenue or even leave a lasting societal or cultural impact.

Any AI initiative must first focus on the organization’s readiness. Allow for learning and practical use before embarking on a grand AI program. Gartner recommends that supply chain leaders follow this five-step formula to introduce their AI initiatives:

Collect impactful, measurable and quickly solvable use cases.

Assemble the necessary skills/talent to use supply chain AI techniques.

Gather relevant data to address the selected use cases.

Select the AI techniques linked to the use cases, the skills and the data.

After a few proofs of concept, determine where the new AI expertise should reside in the supply chain organization.

Peer perspective on supply chain automation technologies

Do more with less by investing in digital. Jeff Block, SVP of Structural Procurement & Growth Programs at Dell Technologies, describes the cost, productivity and strategic benefits of supply chain automation.

Additional resources on supply chain AI

Attend a conference

Ready to take your interest in Gartner to the next level?

Attend a Gartner conference to get exclusive insight on the latest trends, receive one-on-one guidance from a Gartner expert, network with peers from top enterprises and leave ready to tackle your mission-critical priorities.

Gartner Supply Chain Planning Summit

Denver, CO

Related resources on AI in supply chain

Gartner clients: Log in for a complete suite of actionable insights and tools on supply chain AI.

AI in Supply Chain FAQ

What is supply chain AI?

Supply chain AI encompasses the use of AI and machine learning (ML) to interpret data, support decision-making, and automate processes across the supply chain. This includes predictive analytics, optimization, and automation of routine tasks to improve efficiency and responsiveness. Successful implementation of AI in supply chain can lead to significant competitive advantages for organizations willing to invest in these technologies.

What are the roles of AI and machine learning in supply chain?

AI and machine learning (ML) have become pivotal in revolutionizing supply chain management by enhancing efficiency, decision-making, and overall performance. Their integration into supply chain processes offers several transformative benefits:

Predictive Analytics: AI and ML algorithms process extensive data to identify patterns and forecast future outcomes. By anticipating customer needs, organizations can adjust operations proactively, reducing overstock and stockouts.

Automation of Decision-Making: AI in supply chain facilitates autonomous decision-making by processing real-time data and executing actions with minimal human intervention. This is particularly beneficial in dynamic environments where rapid responses are required, such as adjusting inventory levels based on demand fluctuations.

Enhanced Efficiency: AI and ML automate routine tasks and provide actionable insights, freeing up human resources to focus on strategic activities. This leads to improved productivity across supply chain functions, from procurement to logistics.

Risk Management: AI and ML bolster supply chain risk management by identifying vulnerabilities and predicting potential disruptions. This proactive approach allows organizations to develop contingency plans and mitigate risks before they impact operations.

Sustainability and Compliance: AI supports sustainability initiatives by optimizing resource use and ensuring compliance with environmental regulations. For instance, AI can analyze supply chain processes to identify areas for reducing waste and improving efficiency.

Data-Driven Insights: AI and ML enhance data governance and analytics, enabling organizations to make informed decisions based on accurate and timely information.

Collaboration and Integration: AI fosters collaboration across supply chain partners by providing shared insights and enabling integrated decision-making processes.

How does generative AI improve supply chain management?

GenAI transforms supply chain management by enhancing decision-making, automating routine tasks, providing real-time insights, improving collaboration, reducing costs, enhancing customer experiences, supporting sustainability and fostering skill development. These improvements collectively contribute to a more agile, efficient, and responsive supply chain.

How does AI impact transportation in supply chains?

Gartner identified the most prominent AI uses cases for supply chain logistics. Logistics leaders who support transportation and warehousing can use this research to prioritize opportunities including the following:

Damage detection

Predictive ETA

Warehouse slotting

Transportation visibility

Predictive maintenance

Virtual customer assistant

Robotic picking systems control

Supplier relationship management

Autonomous trucks

Document processing

Data-driven warehouse labor standards

How is AI used in supplier selection and evaluation?

General tasks that AI performs include information discovery and summarization. This means that sourcing and procurement leaders can use AI for supplier performance management. Through AI, you can ask questions to understand supplier performance data in real time, and you can process that data as delivery metrics, quality ratings and customer feedback.

How can Generative AI predict global supply chain disruptions?

Generative AI can reshape how supply chains manage the increasing frequency and magnitude of supply chain disruptions. For example:

Generating new risk mitigation strategies: Generative AI can propose network designs that reduce risk exposure, or product designs that minimize dependence on a few critical suppliers.

Presenting an intuitive interface to understand risks: Generative AI can analyze user sentiment, identify risks and share insights back to supply chain leaders for rapid response.

Drive stronger performance on your mission-critical priorities.